Practical knowledge

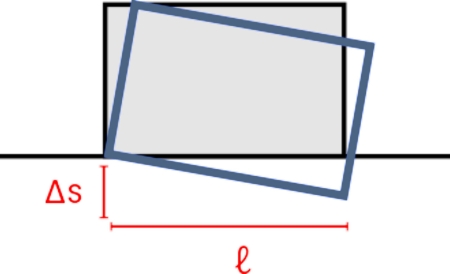

The load of a structure generates additional compressive stresses in the ground, which are associated with settlement. Under the foundation, the stress distribution takes the form of an onion, known as a pressure onion. The stresses are greatest directly under the base surface. They gradually decrease with increasing depth.

As a rule of thumb, the effect of the pressure onion is largely eliminated at a depth corresponding to twice the width of the foundation. Consequently, settlement primarily occurs in this zone, and measures to reinforce the building ground should concentrate on this depth range.