Our services

We specialize in the execution of ground PUR injections and are happy to support you with our professional services.

We specialize in the execution of ground PUR injections and are happy to support you with our professional services.

The aim of the on-site consultation is to thoroughly assess the damage, take into account all important information - such as your own observations, existing plans, water-bearing pipes, any subsoil investigations or public geodata - diagnose the cause of the damage and suggest specific measures to remedy the damage.

If ground PUR injection is the best and most economical solution, we will be happy to provide you with a competitive quote.

We are pleased to offer you this service free of charge throughout Switzerland.

Benefit from our knowledge and make an appointment today.

The most cost-effective and quickest solution for stopping building subsidence is to consolidate the poorly load-bearing subsoil under the foundation using PUR injections.

In the case of PUR ground injection, foaming polyurethane is injected into the ground to be treated via injection lances (steel pipes, Ø 12 mm) in a defined grid and over several depth levels.

The sketch shows a standard injection concept.

The injection lances are placed in the ground through pilot holes (Ø 32 mm). Once the injection work has been completed, the lances remain capped in the subsoil at topsoil level and cannot be re-injected.

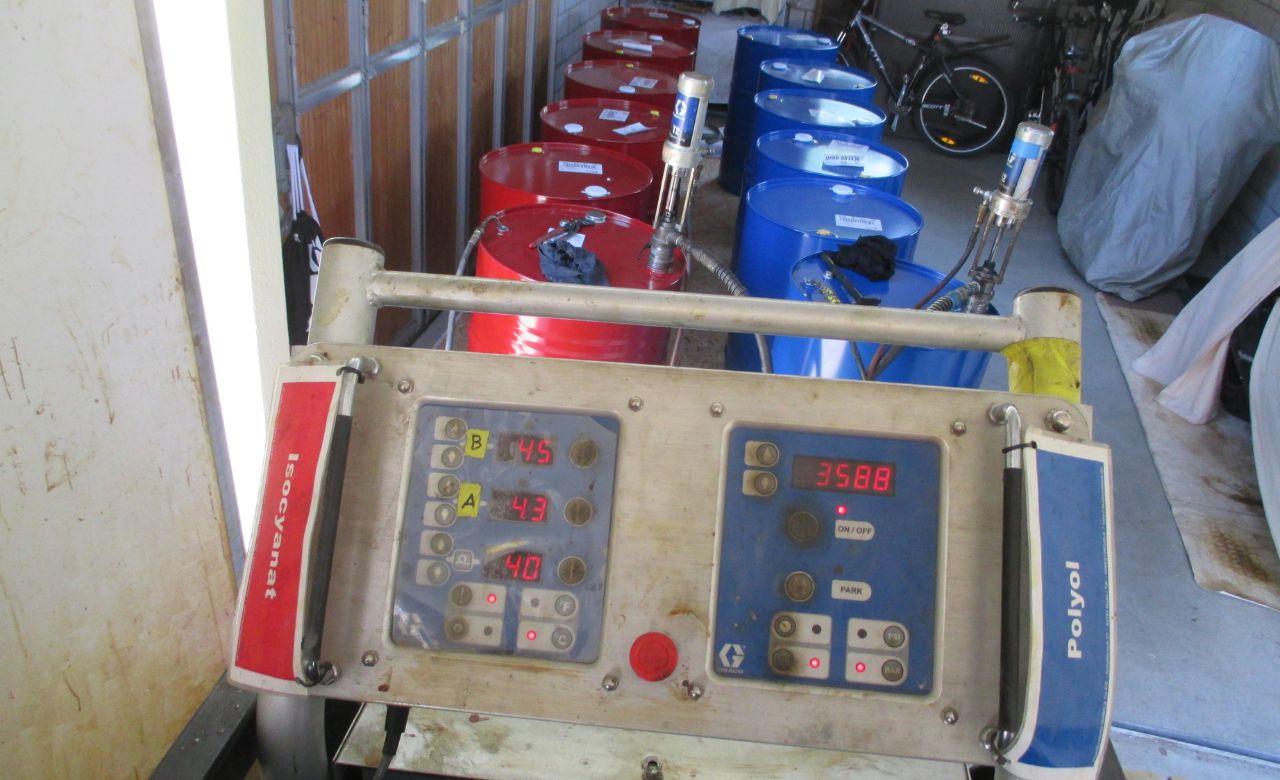

The pre-heated synthetic resin (to 40°C) is pressed out of the injection system into the ground at high pressure (up to a maximum of 140 bar). As soon as it leaves the injection pipe, the liquid resin begins to foam up within a few seconds. The foaming resin penetrates further into the soil structure through its own expansion force.

Depending on the type of soil, the resin penetrates the pore volume of the subsoil and/or presses open flow paths. The fully expanded and hardened resin cements and compacts the subsoil, reducing the pore volume and increasing the shear strength, which leads to an improvement in the load-bearing capacity of the subsoil.

During the injection work, the structure is continuously monitored using laser leveling instruments. Each lance is precisely recorded with regard to the amount of resin injected and the lifting reaction that has occurred.

Once the subsoil has been sufficiently consolidated, additional injection lances and continued injection work can be used to achieve targeted lifting of the structure.

The continued inflow of grout leads to an increase in volume in the subsoil, which causes the subsoil to be locally pre-stressed. Ultimately, the prevailing tension in the soil is overpressurized, which has the effect of bulging the subsoil or raising the structure above it. The inflow of injection material is continued until the desired lifting target is reached. For this purpose, additional injection lances are placed continuously and repeatedly along the injection axes and used to continue the injections.

During the injection work, the structure is permanently monitored with laser leveling instruments, and the injection work is recorded lance by lance with regard to the amount of resin injected and the amount of lift achieved.

Important: A successful building elevation requires the building to be founded on a sufficiently strong concrete floor slab. In addition, potential risks, such as damage to wastewater pipes laid under the floor slab, must be taken into account.

The limit of cost-effectiveness of building elevation by means of ground PUR injection lies at an elevation height of around 25 cm.

When a building is extended, repurposed or renovated, the structural load often increases, which also increases the soil pressure under the building foundation. Without a prior increase in the load-bearing capacity of the foundation, there is a risk of subsidence.

By injecting PUR into the subsoil, the load-bearing capacity of the subsoil is increased to such an extent that the increased structural load can be supported without settlement. This is carried out using the same method as for ground reinforcement to stop settlement.

In the case of excavation pit closures with sheet pile walls, diaphragm walls or pile walls, gaps or unwanted leaks can occur in the excavation pit wall, causing groundwater to flow into the excavation pit together with soil material. Such incidents can cause considerable damage, which is why the openings must be closed and sealed. As an immediate measure, leaving a berm in place or backfilling in front of the opening can be helpful.

The PUR injection of the foundation soil is a proven solution for permanent sealing. In the case of known gaps, the injection can be carried out before the excavation work to seal the opening. Rapidly foaming polyurethane is injected into the subsoil via injection lances (Ø 12 mm) in an adapted grid, often step by step from top to bottom, parallel to the removal of the berm or the excavation.

Depending on the type of soil, the resin penetrates into the pore volume of the subsoil or presses open flow paths. The expanded and hardened resin compacts the subsoil, reduces the pore volume, increases the shear strength and reduces the water permeability.

This method is also suitable for the construction of sealing walls and floors. For example, in existing buildings, pits for new lift underpasses can be excavated and concreted below the groundwater level without a special excavation cut-off wall and only with open dewatering.

When drilling geothermal boreholes, there is a risk that dense layers of soil are breached, under which groundwater is present at a pressure level above the ground surface. In this case, the water in the borehole rises to above the ground surface and flows out of the borehole (so-called artesian).

If all other methods of sealing artesian wells have been tried without success, the flow of water in the borehole can be stopped by injecting rapidly foaming polyurethane and the artesian well successfully sealed.

SoilTec AG proceeds as follows:

The PUR injection foam is injected into the ground via injection lances (Ø 12 mm) at three depth levels around the borehole. To insert the injection lances, the ground is pre-drilled to the maximum achievable depth of around 10 m using a pile-driving rod (Ø 32 mm) and a hydraulic pile-driving hammer (30 kg). The injection lances of different lengths are inserted as a bundle into the pre-punched hole immediately after the ramming rod has been withdrawn.

During injection, the initially liquid polyurethane, preheated to 40°C, is pressed into the pore space of the soil using an injection pump (maximum 140 bar). After about 10 seconds, the resin begins to foam up, pressing itself further into the soil structure and also into the annular space of the borehole probe and stopping the flow of water in the borehole. The polyurethane foaming up in the annular space penetrates far down into the borehole due to the expansion pressure, so that the seal is also achieved at greater depths in the borehole. The treated soil forms a three-stage sealing collar around the borehole in the injection area, which prevents the flow around the sealing point and permanently stops the flow of water rising from the depths.